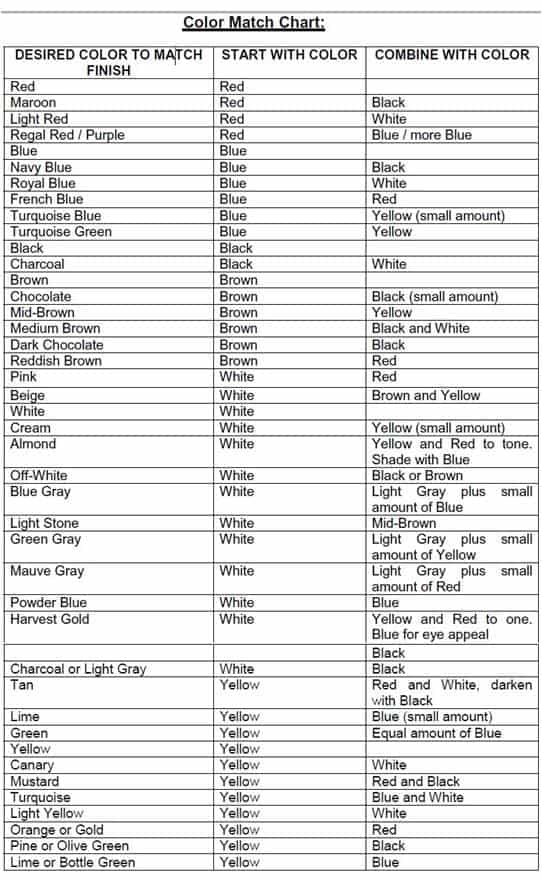

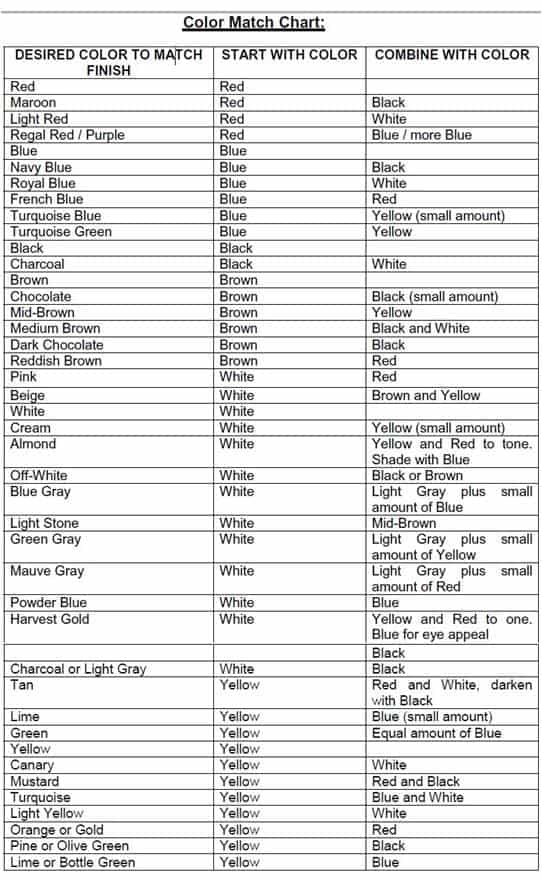

Our Gelcoat Color Match Chart is the perfect solution for any boat repair project. With a wide range of pre-mixed colors, our chart will help you find the right color tint to flawlessly make your gelcoat repairs. For smaller repairs, we offer convenient and easy-to-use repair kits with everything you need to match colors. For larger projects, we have gallons and quarts in 12 different colors ready for you to use. Plus, our neutral gelcoat lets you make any custom color you need when using the gel coat coloring agent. Get the perfect match for all your boat repair needs with Gelcoat Color Match Charts today.

For smaller repairs, we offer a convenient and easy-to-use gelcoat repair kit with everything you need to match colors. For larger projects, we have have over 12 premixed colors of gel coat to choose from, in either gallons or quarts. Plus, our neutral gelcoat lets you make any custom color you need.

Other Product Links:

We are often asked how long does gel coat take to cure?

It really depends on several factors, for example, the type of gel coat used, the temperature and humidity of your environment, and the thickness of the application. Generally speaking, gel coat can take anywhere from a few hours to several days to fully cure.

Here are some general guidelines:

Initial Cure time: Gel coat typically reaches an initial cure within a few hours, usually around 2 to 4 hours. During this time, the gel coat becomes tack-free and can be touched without leaving fingerprints.

Gel Time: this refers to the time it takes for the gel coat to reach a semi-solid state where it can hold its shape and is no longer tacky to the touch. Gel time can vary based on the specific gel coat formulation but is usually within 6 to 12 hours.

Full Cure: this usually takes longer. It can take anywhere from 24 to 72 hours for the gel coat to completely cure and harden to its maximum strength and durability. However, some high-performance gel coats may require longer curing times to achieve their optimal properties.

Factors that can influence curing time include:

Temperature: Higher temperatures generally accelerate the curing process, while cooler temperatures can slow it down. Follow the manufacturer’s recommendations for curing temperature ranges.

Humidity: Higher humidity levels can also affect curing time. High humidity can extend the curing process, while low humidity may speed it up.

Thickness: Thicker applications of gel coat may take longer to cure due to the heat generated during the curing process. Thicker layers can also trap solvents that need to evaporate.

Catalyst/Hardener: Gel coat is usually catalyzed with a hardener to initiate the curing process. The amount and type of hardener used can impact the curing time.

Ventilation: Proper ventilation is essential during curing to ensure that any volatile solvents evaporate and don’t get trapped in the cured gel coat.

We recommend referring to the manufacturer’s instructions and guidelines, as curing times can vary based on the product’s formulation. It’s also important to consider the intended use of the gel-coated surface, as some applications may require longer curing times to ensure the best performance and durability.

How to match your gelcoat color?

We understand matching your gelcoat color can be a daunting task, however with the right tools and techniques, it can be done. The key is to start with a precise color match and then to carefully apply the gelcoat, ensuring that the new color blends seamlessly with the surrounding area. With patience and attention to detail, you can restore your boat’s gelcoat to its original luster or create a customized look that truly represents your personal style on the water.

Where to buy gel coat?

If you need assistance on where to buy gelcoat, Bottom Paint Store is available to answer your questions and help you select the right gelcoat for your needs. We have 100’s of colors and products to choose from.

This can be applied over the colored gel coat and the metal flake is usually coated with clear gelcoat for added UV protection and to smooth the surface. The larger the metalflake, the more coats of clear gel coat it will often take to cover.

This can be applied over the colored gel coat and the metal flake is usually coated with clear gelcoat for added UV protection and to smooth the surface. The larger the metalflake, the more coats of clear gel coat it will often take to cover.![]() Metal flake gelcoat is best applied using a gel coat spray gun to achieve an even coating and be sure to use an appropriate nozzle tip based on flake size.

Metal flake gelcoat is best applied using a gel coat spray gun to achieve an even coating and be sure to use an appropriate nozzle tip based on flake size.