Owning a boat is an adventure that offers endless fun, however it also comes with the responsibility to take care of your vessel so that it performs at its best. One of the essential maintenance processes is painting, especially for aluminum boats. As a boat owner, you want your investment to last as long as possible, and choosing the right paint is paramount.

Aluminum boats are exposed to harsh marine environments, making paint a vital element in maintaining their integrity and performance. The wrong paint choice could result in corrosion and premature wear, so you need to choose wisely. In this blog post, we’ll provide you with all the information you need to make an informed decision when choosing aluminum boat paint.

- Type of Aluminum Boat Paint

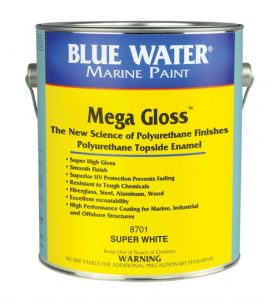

The first decision you need to make is choosing the type of paint. You can use either one or two-part paints, and both have their advantages and disadvantages. Two-part paints have a longer lifespan, resist fading, and provide a glossy finish. They’re also more expensive and hard to apply. Single-part paints, on the other hand, are cheaper, easier to apply and dry faster. However, they’re not as durable and aesthetic as their two-part counterparts.

- Surface Preparation

Before painting, ensure that the surface is clean and free of debris. If your boat has any damage or corrosion, make necessary repairs and fix any leaks. Once the surface is clean and smooth, apply a primer to prevent any future damage. Primer helps the paint bond to the aluminum and improves adhesion, enhancing paint longevity. It’s essential to follow the manufacturer’s instructions for preparation and application.

- Color and Aesthetics

The color and aesthetics of your boat can be a significant factor in the paint selection process. Some people prefer dull colors, while others opt for bright and bold colors to stand out on the water. The right paint color can match your boat’s interior or exterior decor, providing it with a unique look. You can also add features like metallic flake or pearl to enhance the boat’s shimmer in the sunlight.

- Environmental Considerations

Another factor to consider when choosing aluminum boat paint is the environment you’ll be operating in. If you’re in a saltwater area, you may want to consider paints that are salt-resistant, as saltwater can cause corrosion. Some places have strict pollution regulations, so you may need to choose a paint that complies with environmental standards. Some paints are also formulated to withstand extreme temperatures, which is ideal for areas that experience extreme summer heat or winter cold.

- Manufacturer’s Reputation

Choose a reputable manufacturer with a history of making quality boat paint. Check online reviews and feedback from other boat owners to see how different paints perform. Some of the top brands in the market today include Interlux, Pettit, and Sea Hawk, each with their unique formulas designed to serve specific purposes.

Choosing the right aluminum boat paint can be a challenging, however with the right information, you can make an informed decision. Consider the type of paint, surface preparation, aesthetics, environmental considerations, and the manufacturer’s reputation when making your choice. Remember that the right paint will not only enhance your boat’s look but also protect it from damage, ensuring longevity and optimal performance. We hope this guide has been helpful in your search for the right aluminum boat paint for your needs. If you need additional assistance, feel free to contact Bottom Paint Store’s technical support team.

II. Apply Awl-Wash Primer CF (

II. Apply Awl-Wash Primer CF ( If you desire a gloss finish, look to the

If you desire a gloss finish, look to the How to Fix a Leaking Seam or Rivet on Aluminum Boat

How to Fix a Leaking Seam or Rivet on Aluminum Boat