If you’re a boat owner, there’s a good chance you’re familiar with Hawk Epoxy by SeaHawk Paints; however, did you know there are several diverse ways to use it? In this post, we’ll take a look at some of the different ways Seahawk Hawk Epoxy can be used to keep your boat in top condition. So, whether you’re a beginner or an experienced boater, read on for some helpful tips!

What is epoxy?

Epoxy is a type of adhesive that is commonly used to bond two surfaces together. It is made up of a resin and a hardener, which are mixed together to form a tough, durable bond.

Unlike other sealants, epoxy is able to form a strong bond with the surface it is applied to, making it an ideal choice for sealing concrete, metal, and glass. Epoxy is also resistant to temperature changes and UV light, making it ideal for use in outdoor applications. In addition to its practical benefits, epoxy can also be used to create interesting visual effects. When applied to a surface in thin layers, epoxy can create a marbled or even tie-dye effect. As a result, epoxy is a versatile material that can be used for both functional and decorative purposes.Epoxy is typically used for repairing metal, plastic, and glass.

It can also be used for bonding wood, concrete, and ceramic. Epoxy is available in both liquid and powder form. The liquids are typically used for small repairs, while the powders are better suited for larger projects. Epoxy is typically applied with a brush or roller. Once it has been applied, it needs to be allowed to cure for 24 hours before it can be used.

Hawk Epoxy can be used as a sealant to protect surfaces from water and other elements.

Fairing Hull Imperfections with Hawk Epoxy

Let’s face it, our boats take a beating. They’re exposed to the sun, the salt, the waves, and the wind on a daily basis. So, it’s no wonder that even the best-kept boats can start to show their age after a few years. One of the most common problems is fairing hull imperfections. These are small cracks or indents in the gelcoat that can make your boat look old and worn. But don’t despair, there is a simple way to fix this problem with hawk epoxy.

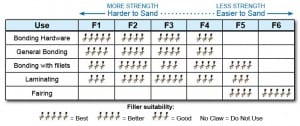

Hawk epoxy is a two-part epoxy resin that you mix together to create a putty-like substance. Once it’s mixed, you can use it to fill in any cracks or indentations in your hull. It dries hard and sets fast, so you can sand and paint over it once it’s dry. And best of all, it’s very affordable. So, if your boat is starting to look a little worse for wear, don’t worry, just grab some hawk epoxy, and give your boat a facelift.

Patching Holes in a Boat with Hawk Epoxy

There’s nothing worse than getting your boat out on the water only to find that it’s taking on water. Fortunately, patching holes in a boat is relatively easy to do, as long as you have the right materials.

Hardware Replacement Adhesion with Hawk Epoxy

Hawk epoxy’s two-part epoxy provides a strong, permanent bond and can be used on a variety of materials, including metal, glass, ceramic, and plastic. And it sets in just minutes, so you won’t have to wait around for hours for it to dry. Plus, it’s easy to use – just mix the two parts together and apply it to the surfaces you want to bond.

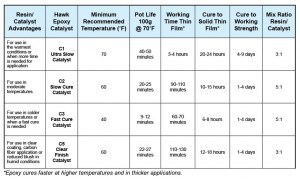

Hawk Epoxy Proper Measuring and Mixing

Anyone who has ever worked with epoxy knows that it is crucial to get the measuring and mixing process exactly right. Too much or too little of either ingredient can ruin the entire batch, and that can be a costly mistake. Hawk Epoxy strives to make the measuring and mixing process as simple and foolproof as possible. Our epoxy products come with clear instructions and easy-to-use tools that make it easy to get the perfect mix every time. If you follow the provided instructions, you can be confident that your epoxy project will turn out just the way you want it to.

Applying Hawk Epoxy

Hawk epoxy is specifically designed for use on boats, and it’s perfect for patching small holes. The epoxy comes in two parts that you mix together, and then it can be applied directly to the hole.

Sometimes, you need something more than just epoxy resin. That’s where Hawk epoxy fiberglass cloth and mat come in. The cloth and mat help to reinforcing the epoxy, making it stronger and more durable. They can be used to repair cracks, leaks, or holes in a variety of surfaces, including concrete, metal, glass, and wood. Best of all, the cloth and mat are easy to apply and can be cut to fit any size or shape. So, whether you’re patching up a small crack or fixing a large hole, Hawk epoxy fiberglass cloth and mat can help you get the job done right.

First, clean the area around the hole with sandpaper to make sure that the epoxy will adhere properly. Then, mix the epoxy according to the instructions and apply it to the hole. Once it dries, the epoxy forms a strong bond that will keep the hole sealed. It is important to note that the curing time may vary depending on your temperature and humidity levels.

Once properly applied and cured your boat will be good as new – no leaks guaranteed!

Sealing a Fiberglass Hull with Hawk Epoxy

Sealing a fiberglass hull with epoxy is a great way to extend the life of your boat. Epoxy is a strong, durable material that will create a waterproof barrier between the hull and the water. It is important to properly prepare the surface before applying the epoxy, and to follow the manufacturer’s directions closely. Once the epoxy has been applied, it is important to allow it to cure properly before using the boat. With proper preparation and care, sealing a hull with epoxy will help to keep your boat in good condition for many years to come.

How to apply Hawk Epoxy

Epoxy is a type of synthetic resin that is often used as an adhesive or coating. It is typically made up of two parts that are mixed together and then cured to form a hard, durable finish. Hawk Epoxy by SeaHawk paints is a two-part epoxy that can be used for a variety of applications, including bonding, coating, and laminating. Before using Hawk Epoxy, it is important to read the instructions carefully and to follow all safety precautions. Once you have mixed the two parts of the epoxy together, you will have a limited time to apply it before it begins to set. For best results, apply the epoxy to a clean, dry surface and use a brush or roller to spread it evenly. Once it has been applied, the epoxy will need to cure for 24 hours before it is fully cured. However,

Hawk Epoxy is a versatile product that can be used in many different ways. We’ve highlighted just a few of the potential applications for this amazing adhesive. If you have questions for how to use Hawk Epoxy or need help bringing your boat painting project to life, contact the Bottom Paint Store customer service team Monday through Friday 9-5 EST 888-505-2313.

What is the best way to achieve maximum adhesion when replacing your boat’s hardware? This How To article will give you the basic knowledge you need to get your repair done correctly.

What is the best way to achieve maximum adhesion when replacing your boat’s hardware? This How To article will give you the basic knowledge you need to get your repair done correctly.