Bottom paint is an essential part of protecting your aluminum boat from the elements. Be sure to choose a bottom paint that is specifically designed for aluminum boats. Some bottom paints can actually cause corrosion on aluminum, so it’s important to make sure you get the right type of paint. Apply the bottom paint according to the manufacturer’s instructions. In general, you’ll want to apply two coats for best results.

Here are a few tips on how to apply bottom paint to ensure optimal results.

KEY TAKEAWAYS FOR HOW TO PAINT AN ALUMINUM BOAT

- Prepare the Surface

The first step in painting an aluminum boat is to prepare the surface. This includes cleaning the boat with soap and water, sanding it down, and applying a primer. The primer will help to create a smooth surface for the paint to adhere to. - Choose the Right Paint

It is important to choose the right paint for an aluminum boat. A good choice would be a marine-grade paint that is specifically designed for aluminum boats. This type of paint will be able to withstand the elements and will not peel or chip easily. - Apply the Paint

Once you have chosen the right paint, you can begin to apply it to the boat. It is best to use a brush or roller for this task. Start by painting the hull of the boat and then move on to the deck. Be sure to apply an even coat of paint and allow it to dry completely before applying a second coat.

Tuff Stuff Marine Epoxy Primer

Begin by pressure washing your boat, and scrubbing any debris, dust, contaminants and marks off the boat surface so it is totally clean. Give your boat a final rinse and dry. If you do not have any coatings at all on the bottom of the boat, we suggest to sand the hull with 80 grit and then apply Tuff Stuff High Build Epoxy. It is a water tight barrier coat designed for use under the waterline and with aluminum hulls. Use 2 coats. You can apply the 2nd coat within a couple of hours of the first coat. (up to 6 days)

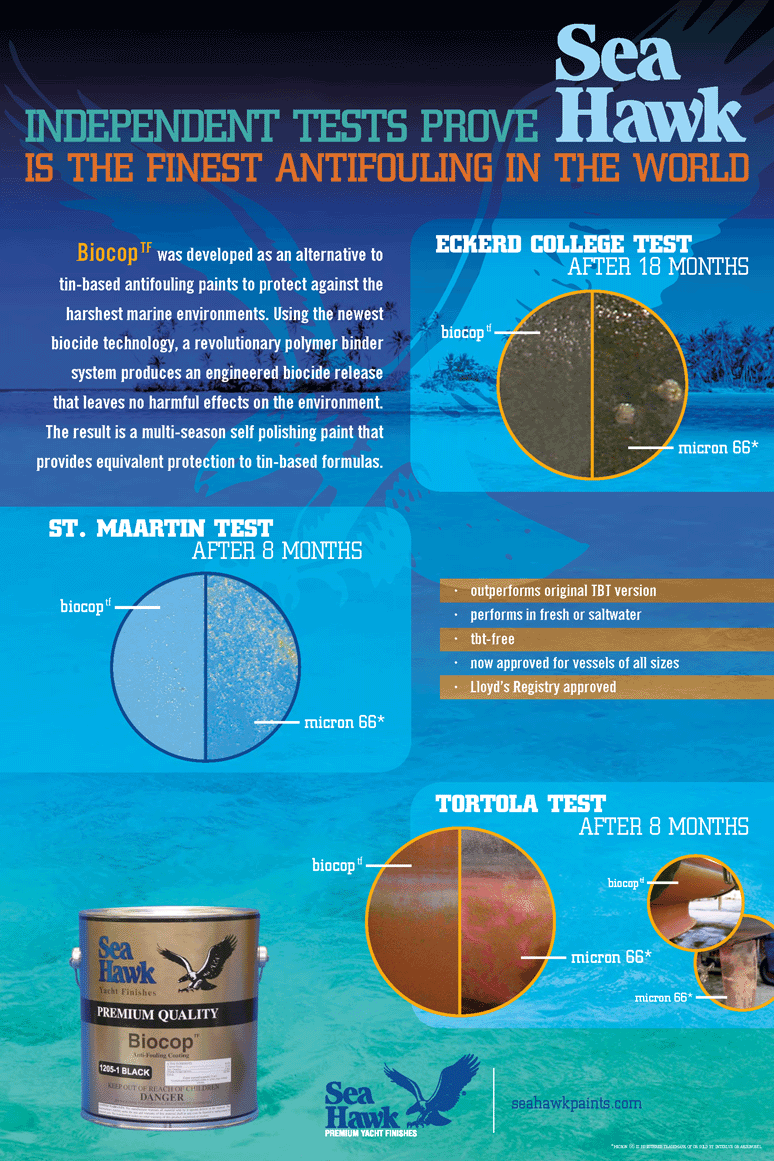

After you apply Tuff Stuff marine epoxy primer on hull, be sure to use an aluminum safe bottom paint. The bottom paint needs to be applied the same day as the Tuff Stuff marine epoxy primer. Bottom paints in general are designed to repel hard growth. Colorkote is an excellent triple biocide bottom paint for aluminum hulls when in salt water. We recommend Mission Bay for fresh water. I have listed links below to the products described above. These can be brushed, sprayed, or rolled. If you already have coating(s) on the hull, pressure wash, sand with 80 grit, and then apply your paint choice.

Links:

How to Video: Aluminum Boat Bottom Paint Application

See here for all aluminum safe bottom paints.