Maintaining a boat involves more than just keeping it clean and stocked with gear—it’s about protecting your investment from the harsh marine environment. Two of the most common materials used in boat repair and maintenance are gelcoat and epoxy resin. While both serve vital roles in fiberglass boat construction and restoration, they are not interchangeable.

In this guide, we’ll break down the differences between gelcoat and epoxy, explain when to use each, and help you make informed decisions that will keep your boat seaworthy and looking sharp.

Let’s start with an understanding of the basics

What is Gelcoat?

Gelcoat is a pigmented polyester or vinyl ester resin used as the outer layer of most fiberglass boats. It provides a smooth, glossy finish and helps protect the underlying fiberglass laminate from UV rays, water, and minor abrasions.

- Primary Purpose: Aesthetic finish and surface protection

- Application: Typically applied in a mold during boat construction or used later for cosmetic repairs

Our products are formulated to provide superior resistance to UV rays and meet the stringent requirements of the boating industry.

What is Epoxy?

Epoxy resin is a two-part adhesive consisting of a resin and a hardener. When mixed, it forms a strong, durable material ideal for structural repairs and bonding various surfaces, including fiberglass, wood, and metal.

- Primary Purpose: Structural repairs, strong bonding, waterproofing

- Application: Used in layups, laminating, filling, or as a base layer for barrier coats

Tuff Stuff is designed as a high-build two-part epoxy primer, making it ideal for barrier coats, especially below the waterline. It’s specifically engineered to prevent water absorption and osmotic blistering in fiberglass hulls—a core strength of marine-grade epoxies.

Gelcoat vs. Epoxy: Key Differences

| Feature | Gelcoat | Epoxy Resin |

| Primary Use | Surface finish, color, UV protection | Structural repairs, bonding, sealing |

| Strength | Less strong, brittle under stress | Extremely strong, flexible under stress |

| UV Resistance | Excellent | Poor – requires UV-resistant topcoat |

| Water Resistance | Good | Excellent |

| Adhesion | Best on cured polyester/fiberglass | Bonds to wood, metal, fiberglass, epoxy |

| Ease of Use | Faster to apply, but less forgiving | Longer cure time, requires precision |

When to Use Gelcoat

Gelcoat is your best choice when the goal is cosmetic restoration of your boat’s surface—particularly fiberglass. It’s ideal for:

- Repairing surface scratches and chips in the existing gelcoat

- Restoring faded or oxidized areas

- Matching the boat’s original finish and color

- Protecting from UV damage and surface wear

However, gelcoat does not bond well to epoxy or non-polyester surfaces unless properly prepped. Also, it’s not suitable for deep repairs or structural issues.

Best Time to Use Gelcoat:

- Restoring surface shine on fiberglass

- Filling shallow scratches, dings, and UV damage

- Matching original boat color (especially white, because, well… everything’s white)

- Cosmetic touch-ups above and below the waterline

Tip: Always sand and clean the surface thoroughly before applying gelcoat. If applying over epoxy, ensure the epoxy is fully cured and properly sanded to create a mechanical bond.

When to Use Epoxy

Epoxy is the material of choice when strength, durability, and waterproofing are the priorities. It excels in situations like:

- Repairing delaminated fiberglass

- Fixing holes, cracks, or structural damage

- Bonding dissimilar materials like wood to fiberglass or metal

- Sealing bare fiberglass or wood to prevent water intrusion

- Creating a barrier coat to prevent blistering (osmosis)

Epoxy is more chemically resistant than polyester resins and has superior adhesive qualities. However, it requires a UV-resistant topcoat, such as topside boat paint or gelcoat, to protect it from sunlight degradation.

Best Time to Use Epoxy:

- Repairing structural damage like cracks, holes, or delamination

- Sealing bare fiberglass to prevent water intrusion

- Adhering materials (wood, metal, composite) with confidence

- Filling deep gouges or rebuilding missing chunks

- Barrier coats to prevent osmotic blistering

Can You Use Gelcoat Over Epoxy?

Yes, but with preparation. Since gelcoat does not naturally adhere well to epoxy, the epoxy must be fully cured, sanded with 80–120 grit, and cleaned thoroughly to allow for mechanical bonding. Some professionals recommend applying a tie-coat primer to improve adhesion.

Choosing the Right Product

- Use Gelcoat when:

You’re doing surface-level cosmetic work on fiberglass and want a UV-resistant, glossy finish. - Use Epoxy when:

You’re repairing structural damage, bonding materials, or sealing surfaces below the waterline.

Final Thoughts

Whether you’re restoring your hull’s shine or reinforcing a damaged section, knowing when to use gelcoat vs epoxy ensures your boat stays safe, seaworthy, and beautiful. Each material serves a distinct purpose—gelcoat for finishing and appearance, epoxy for strength and structural integrity.

By understanding their properties and correct applications, you’ll be able to tackle any repair with confidence—and save time and money in the long run.

Ready to tackle your next boat project like a pro?

Stock up on top-rated gelcoat and epoxy products at Bottom Paint Store and cruise into your next DIY with confidence. Need help? We are only a phone call 888-505-2313 or live chat away.

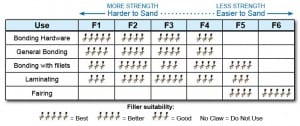

What is the best way to achieve maximum adhesion when replacing your boat’s hardware? This How To article will give you the basic knowledge you need to get your repair done correctly.

What is the best way to achieve maximum adhesion when replacing your boat’s hardware? This How To article will give you the basic knowledge you need to get your repair done correctly.

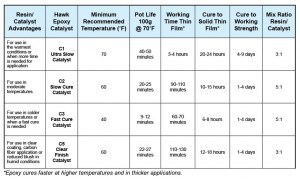

The Pump Kits come in two sizes, one kit accommodating the Size 1 and 2 Resin and Catalysts, and one kit accommodating the Size 3 Resin and Catalysts. Be sure to get the right size kit for the amount of resin and

The Pump Kits come in two sizes, one kit accommodating the Size 1 and 2 Resin and Catalysts, and one kit accommodating the Size 3 Resin and Catalysts. Be sure to get the right size kit for the amount of resin and

How to Fix a Leaking Seam or Rivet on Aluminum Boat

How to Fix a Leaking Seam or Rivet on Aluminum Boat