If you do not have any coatings at all on the bottom of the boat, we suggest to sand the pontoons with 80 grit and then apply Tuff Stuff High Build Epoxy. It is a water tight barrier coat designed for use under the waterline and with aluminum hulls. Tuff Stuff will insure that you protect the aluminum from corrosion, and also aid in the adhesion of the antifouling paint. Use 2 coats. You can apply the 2nd coat within a couple of hours of the first coat. See detailed instructions at “How to Apply Marine Epoxy Primer”.

After you apply Tuff Stuff marine epoxy primer on hull, be sure to use an aluminum safe antifouling paint. The bottom paint needs to be applied the same day as the Tuff Stuff marine epoxy primer. Antifoulants in general are designed to repel hard growth. For soft growth you should have an additional biocide that help with the algae. Colorkote is an excellent antifoul for aluminum pontoons used in salt water and/or fresh water. For a less expensive option, see Smart Solution Metal Free Antifouling paint.

After you apply Tuff Stuff marine epoxy primer on hull, be sure to use an aluminum safe antifouling paint. The bottom paint needs to be applied the same day as the Tuff Stuff marine epoxy primer. Antifoulants in general are designed to repel hard growth. For soft growth you should have an additional biocide that help with the algae. Colorkote is an excellent antifoul for aluminum pontoons used in salt water and/or fresh water. For a less expensive option, see Smart Solution Metal Free Antifouling paint.

WARNING: You should only use an aluminum safe antifouling like Smart Solution. Using any other type of copper based antifouling could severely damage your pontoons and will cause corrosion, pitting and eventually holes in your pontoon boat.

If you do not need antifouling paint and are in fresh water, we suggest using one of the products located in the “How to Paint an Aluminum Jon Boat“ article.

Links:

How to Video:

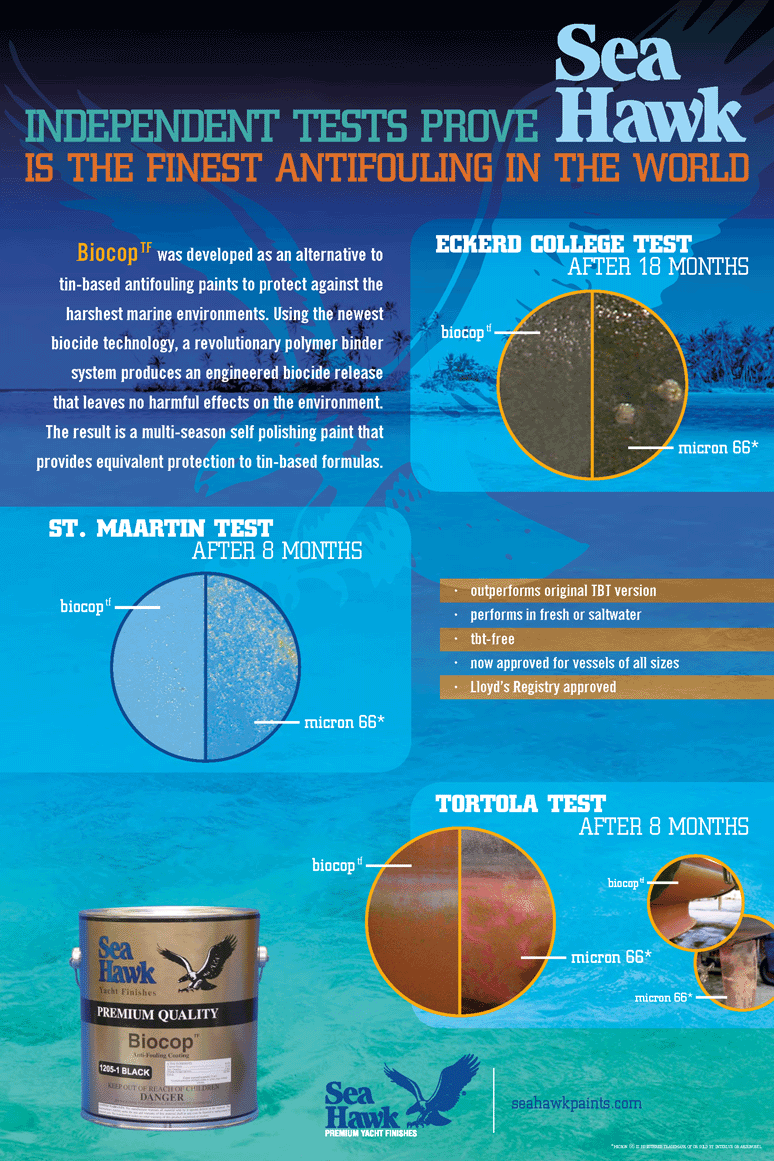

When painting an aluminum outdrive you must use a copper-free bottom paint. There are a couple of different brands out there: Interlux, Blue Water Marine, and Sea Hawk to name a few. However, you will get the best possible results with

When painting an aluminum outdrive you must use a copper-free bottom paint. There are a couple of different brands out there: Interlux, Blue Water Marine, and Sea Hawk to name a few. However, you will get the best possible results with